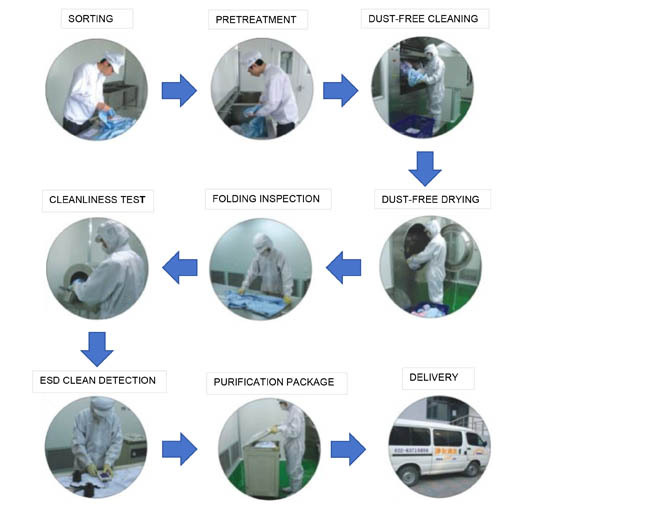

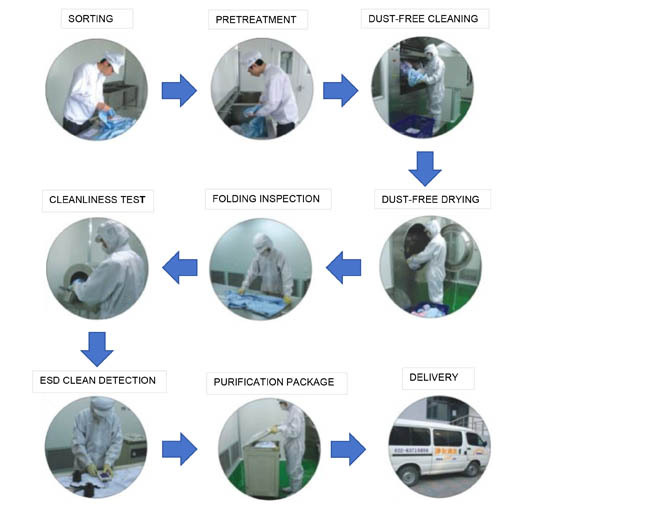

Cleaning process of class 100 cleanroom ESD uniforms

How to clean the ESD uniforms for class 100 cleanroom?

-

Sorting: After receiving the customer's clothes to be washed (or purified shoes, purified boots), advanced sorting, and then stored in a covered plastic box to prevent pollution.

-

Pretreatment: For the use of work clothing (or purification shoes, purification boots) in the process of some damage, loss of buttons and other maintenance treatment, special pollution to be cleaned in advance decontamination treatment.

-

Dust-free cleaning: the pre-treated work clothes (or purified shoes, purified boots) are cleaned by the non-control area through the special channel structure washing machine, and enter the control area (clean room).

-

Dust-free drying: clean chemical clothing (or purified shoes, purified boots) in the clean room by the dust-free dryer (used in the drying hot air filtered by HEPA) drying.

-

Folding inspection: the dried clean chemical clothing (or purified shoes, purified boots) should be folded, and the appearance inspection should be carried out at the same time, and those that do not pass the inspection need to re-enter the cleaning process or be replaced.

-

Cleanliness test: Drum tester can test the number of dust particles of cleanliness level after cleaning.

-

ESD clean detection: ESD performance check to ensure the anti-static performance of clean chemical clothing (or purified shoes, purified boots).

-

Purification package: through all the inspection of the clean chemical clothing (or purification shoes, purification boots), after the purification bag sealed packaging, it becomes a qualified product, can be used again in the clean room.

-

Delivery: In order to provide customers with more convenient and efficient service, after cleaning the clean chemical clothing (or purification shoes, purification boots) will be sent to the customer by the company's special car.